STEM Homeschool Curriculum: How to Teach Your Kids STEM at Home

February 13, 2024Project-Based Learning in STEM Classrooms: A Complete Educator's Guide

February 12, 2024How to Get Your STEM Program Funded: Step-by-Step Guide

January 29, 2024Integrating DIY STEM Kits into Classroom Learning: A Guide for Educators

December 20, 2023STEM Teaching Strategies for Your Classroom: How to Elevate the Education Experience

December 14, 20236 Ways to Improve Your Child's Focus and Concentration

February 22, 2023

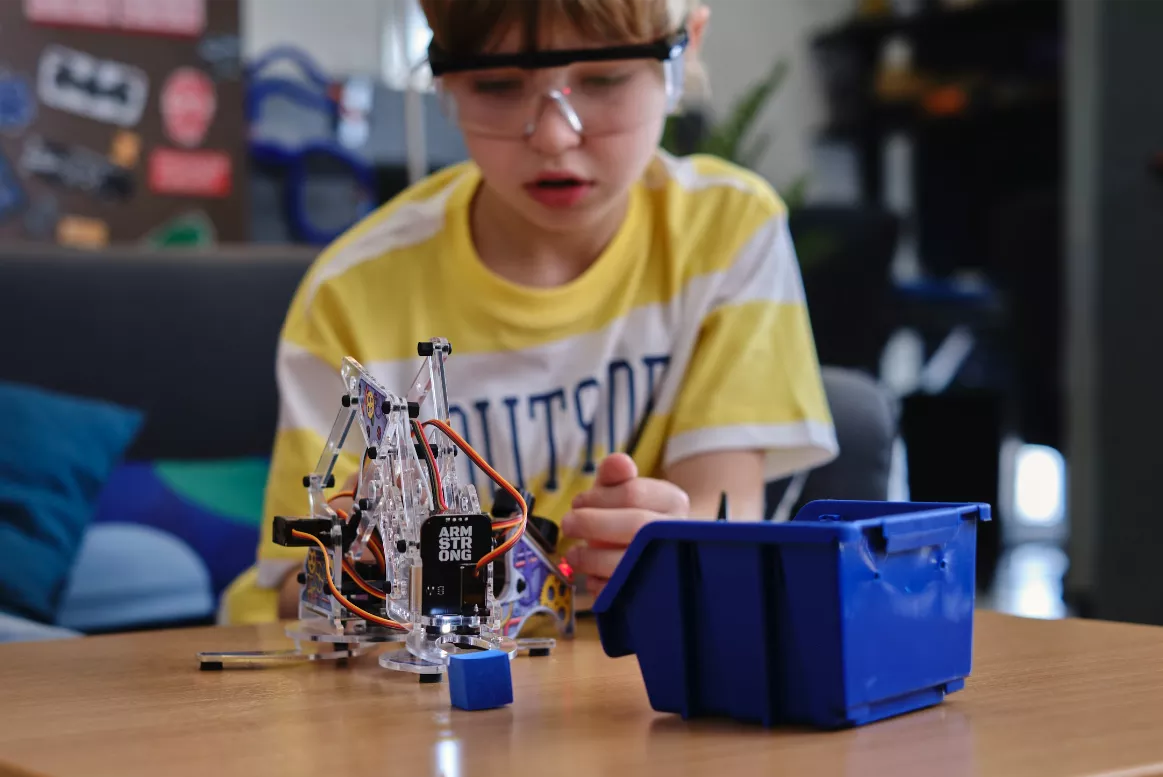

STEM for Middle Schoolers: A Guide for Teaching STEM at Middle School

Ever wondered how to captivate middle school students with STEM education? Dive into our guide to discover the core principles and engaging activities that make STEM fun and relevant.

From fostering a STEM identity to hands-on projects like coding and robotics, we provide everything you need to inspire your students and prepare them for a bright future in science and technology.

Sign up for a 10% off your first purchase

Read stories how our founder Albert turned his childhood passion into CircuitMess, and get exciting DIY project ideas you can do with your kids at home for free.